[ad_1]

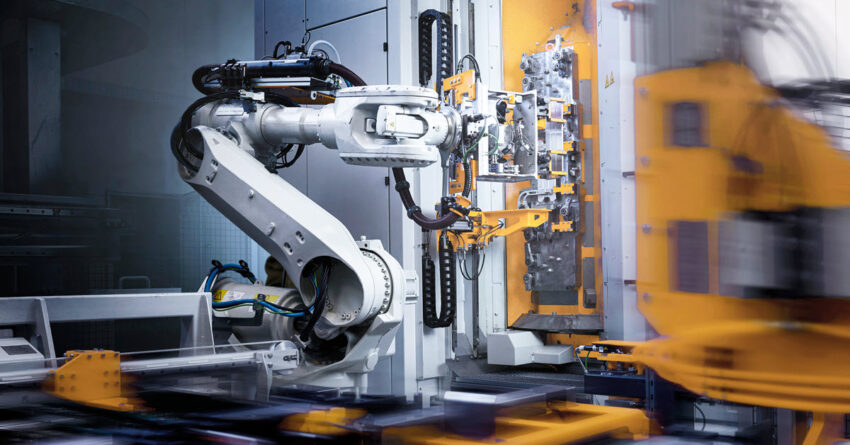

As suppliers digitize operations, they are connecting a lot more industrial property and working with additional application to run their factories. A dependable, efficient community on the plant ground is important. So is productive protection to stop cyberattacks that could disrupt manufacturing and lead to significant earnings decline and/or main protection dangers. As Dino Busalachi, cofounder and CTO of Velta Technologies, points out, “In the IT entire world, obtaining a blip in the network [is] no significant offer. But on the plant flooring, you may well shut down a million-dollar piece of products.”

Usually, industrial networks were being designed and managed by the line of enterprise. But desire for a lot more IT technologies, better efficiency, and better scalability, alongside with the rise of cyberthreats, is complicated the regular technique. Which is due to the fact operations teams are industry experts in developing complicated industrial procedures and working operational systems (OT), but they typically absence the working experience of fashionable IT networking and security abilities. Equally, IT teams have modern-day networking and protection abilities but usually very little know-how of the devices on the manufacturing unit floor.

Constructing on about 20 decades of expertise supporting industrial organizations digitize their operations, Cisco and its companions are supporting to bridge that hole. In North The united states, for instance, Velta Technologies is taking gain of Cisco industrial safety methods to help makers and their devices integrators to structure secure industrial networks from the get started.

Together with OT devices integrators and panel builders these as Barry-Wehmiller Layout Group, Cisco and Velta Know-how can aid productive conversations among IT and functions teams. With this aid, operations can enhance performance even though preserving management of output environments, and IT can enhance community assets while securing the world wide organization.

“The functions groups have distinct demands than a regular IT firm [does]. Aspect of our work is to make certain that functions and IT go on to talk,” explains Josh Rabaduex, director of Barry-Wehmiller Style and design Team. “We want to make positive that we help manufacturing hold their output objectives [and] IT security in intellect, and we want to continue to keep each teams working jointly.”

As Busalachi notes, “[Velta Technology’s] expertise is industrial cybersecurity. Gaining visibility into these environments is the basis for every thing. The mix of Cyber Eyesight and Cisco IE3x00 switches will make it very straightforward to obtain that visibility at scale. It is the foundation for a robust industrial network and a detailed strategy to OT safety.”

Velta Technology’s capabilities, together with Cisco’s reason-constructed industrial switches and Cisco Cyber Eyesight, aid corporations to deploy industrial networks in which protection isn’t an afterthought—it’s integrated by style. With this tactic to OT visibility and stability, industrial organizations can unlock higher IT abilities, greater efficiency, and higher scalability—all though addressing applicable regulatory and compliance fears.

To discover more about how Cisco and its OT programs integrators associates can help you to build superior and secure industrial networks, please get hold of us, and don’t overlook to subscribe to the Cisco IoT Security Publication.

Share:

[ad_2]

Supply hyperlink