Embroidery, a craft that dates back centuries, has evolved significantly with the introduction of modern embroidery machines. Among the myriad choices an embroiderer faces, selecting the right thread weight is paramount for achieving optimal results. In this comprehensive guide, we’ll delve into the intricacies of thread weights, unraveling the mysteries to help you make informed decisions and elevate your machine embroidery projects.

I. Introduction to Thread Weights in Machine Embroidery

A. Understanding Thread Weight

Thread weight refers to the thickness or diameter of the thread. In machine embroidery, selecting the appropriate thread weight is crucial for achieving the desired look, texture, and durability in your designs.

B. Common Thread Weight Measurement

Thread weight is often measured in denier or tex. Denier represents the weight in grams of 9,000 meters of thread, while tex measures the weight in grams of 1,000 meters. The lower the denier or tex number, the finer and lighter the thread.

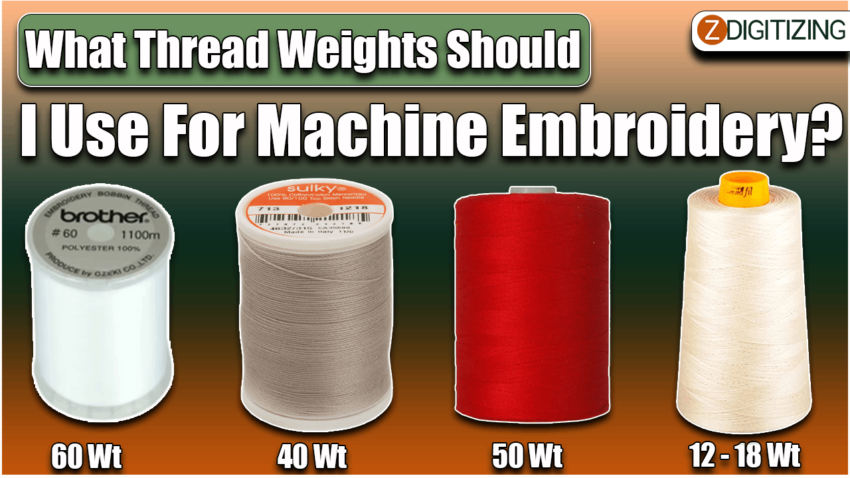

II. Popular Thread Weights for Machine Embroidery

A. 40 Weight Thread

40 weight is one of the most commonly used thread weights in machine embroidery. It strikes a balance between thickness and versatility, making it suitable for a wide range of projects. It provides sufficient coverage and durability while allowing for intricate details in designs.

B. 50 Weight Thread

Slightly finer than 40 weight, 50 weight thread is a popular choice for detailed embroidery digitizing work. It’s ideal for smaller lettering, fine lines, and intricate designs, offering a smoother finish and allowing for more detail in the stitching.

C. 60 Weight Thread

Considered a lightweight thread, 60 weight is excellent for projects that demand a delicate touch. It’s often used for fine details, monogramming, and projects where a subtle, elegant finish is desired. However, it may be less suitable for projects requiring high coverage due to its finer nature.

D. 30 Weight Thread

On the thicker end of the spectrum, 30 weight thread is a robust option. It provides excellent coverage, making it suitable for bold designs and projects where the thread needs to stand out. However, it may be less ideal for intricate details due to its thickness.

III. Factors Influencing Thread Weight Selection

A. Fabric Type and Weight

Consider the type and weight of the fabric you’ll be embroidering on. Lighter fabrics may benefit from finer threads, while heavier fabrics can handle thicker threads for better visibility and durability.

B. Design Complexity

The complexity of your embroidery design plays a crucial role in thread weight selection. For intricate and detailed designs, finer threads offer more precision, while bolder designs may benefit from thicker threads for enhanced visibility.

C. Desired Textural Effect

Thread weight contributes to the textural effect of the embroidery. Finer threads create a smoother finish, while thicker threads add dimension and texture to the design. Consider the visual and tactile impact you want to achieve.

IV. Special Considerations for Specialty Threads

A. Metallic Threads

Metallic threads, known for their shimmer and shine, often come in various weights. Due to their unique properties, it’s essential to select a thread weight that complements the design and ensures smooth stitching without breakage.

B. Variegated Threads

Variegated threads feature color changes within the strand. They are available in different weights, allowing for creative effects in embroidery. Choosing the right weight ensures that color transitions align with the design’s aesthetic.

C. Specialty Threads for Texture

Some specialty threads, such as wool or silk, come in specific weights. These threads can add luxurious textures to your embroidery projects. Pay attention to the thread weight to achieve the desired tactile effect.

V. Tips for Thread Weight Selection

A. Experiment with Samples

Before embarking on a full-scale project, create sample embroideries using different thread weights. Evaluate how each weight interacts with the fabric and design, and choose the one that best suits your vision.

B. Consult Machine and Thread Manuals

Refer to your embroidery machine manual for recommendations on compatible thread weights. Additionally, thread manufacturers often provide guidance on which weights work best with their machines.

C. Test on Different Fabrics

Thread weight can behave differently on various fabrics. Test your chosen thread weight on scraps of the actual fabric you’ll be using to anticipate any challenges or adjustments needed for the project.

VI. Conclusion: Mastering Thread Weights for Stunning Embroidery

Choosing the right thread weight for machine embroidery is an art that combines technical understanding with creative vision. As you explore the nuances of thread weights, consider the fabric, design complexity, and desired textural effects. Whether you’re aiming for delicate details, bold statements, or unique textures, the right thread weight will be the key to unlocking the full potential of your machine embroidery projects.

Zdigitizing

We trust this article might really work out for you. To digitize embroiery plan you would require an expert like ZDigitizing, as digitizing is a mind boggling process.

Zdigitizing is a digitizing embroidery organization that gives total digitizing and vector craftsmanship benefits all around the world to organizations, ventures, and enterprises. Zdigitizing gives fashionable, strong, and sensible custom digitizing embroidery and vector craftsmanship administrations. We have been conveying first class digitizing embroidery administrations for 20+ years.

If you are looking to digitize your embroidery designs, ZDigitizing is a reliable and professional company that provides complete digitizing and vector art services worldwide.

With a quick turnaround time and excellent quality, ZDigitizing is a great choice for your digitizing needs.

Hope it will be helpful for you guys!

If there’s any question related to this article you can simply ask in the comment section and don’t forget to share with those you think might be helpful for them.

And finally, thanks for reading!

Frequently Asked Questions:

-

What does thread weight refer to in machine embroidery?

- Thread weight in machine embroidery refers to the thickness or diameter of the thread. It influences the appearance, texture, and durability of the embroidered design.

-

Which thread weight is commonly used in machine embroidery?

- 40 weight thread is one of the most commonly used thread weights in machine embroidery. It provides a good balance between thickness and versatility.

-

How does fabric type influence thread weight selection?

- Lighter fabrics may benefit from finer threads, while heavier fabrics can handle thicker threads for better visibility and durability.

-

Are there specialty threads with specific weights for embroidery?

- Yes, specialty threads such as metallic, variegated, and those made from materials like wool or silk come in specific weights, each contributing unique effects to embroidery projects.

-

What should I consider when choosing thread weights for metallic threads?

- When choosing thread weights for metallic threads, consider the machine compatibility, design intricacy, and the desired level of shimmer. Experimentation with samples is key to achieving optimal results.